19.09.2024

Business Challenge

The international toy manufacturer, Schleich GmbH, headquartered in Germany, struggled to handle its logistics processes efficiently due to significantly changed requirements as part of their expansion strategy. New attractive products led to a total of more than 700 SKUs and a very heterogeneous product range overall, requiring the company to adapt the current logistical workstreams at the central warehouse location.

The main logistical challenge was handling the diverse order sizes resulting from internationalization, the varying packaging regulations, cut-off times and the large number of different shipping carton types. The current central warehouse location in Germany, with a total area of 23,000 m², was difficult to expand due to a lack of space on the lot and the scheduling of more than 700 orders per day was purely manual.

Implemented solution

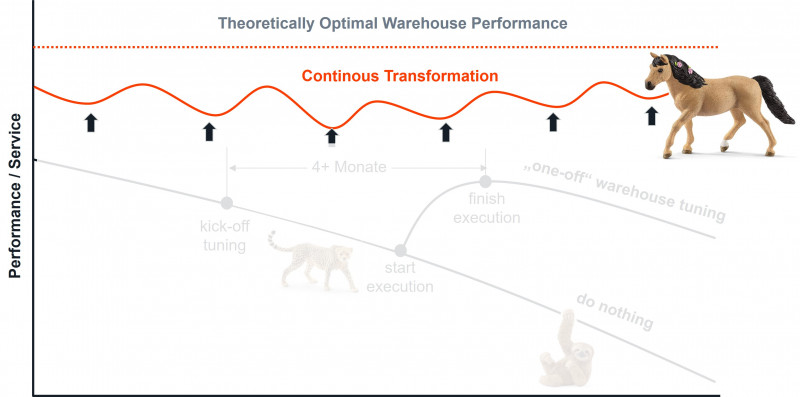

Due to the complex processes in the picking system, on-site restrictions, and the high service requirements, improving logistics with additional technology was an option - a smart solution had to be found to expand the capacity of the system. By using a "digital twin", the as-is situation was analyzed and a fine-tuning of the existing system implemented.

The digital twin allowed them to test and derive the best control strategy for the new given order and product range structures. This enabled the digital twin to adapt ideally to changing conditions and thus ensure high-capacity utilization of the system and personnel in advance.

In short, their digital twin has achieved unprecedented capabilities for Schleich GmbH: Creating transparency across logistics processes, continuously deriving IT strategies, identifying bottlenecks, defining performance parameters, and determining performance limits using stress tests.

Overall, the digital twin supported the Schleich GmbH to increase the adaptability within a safe but dynamic environment and to guarantee stable performance in the future.

Benefits

The following goals were achieved by establishing a digital twin and implementing the smart solution:

9% reduction in replenishment costs,

33% higher picking performance and throughput,

more than 175k EUR savings p.a.

Learnings and Outlook

Use for brownfield and greenfield

The digital twin and the associated material flow simulation can not only be used for new planning, but also to create added value for existing systems, and like in this example, support Schleich GmbH with both tactical and operational issues.

Data-driven approach

The data model guaranteed a data-driven decision-making process and enabled scenario simulations. Up-to-date data allowed Schleich GmbH to make timely decisions.

Data interface

The digital twin was connected to the live systems using a data layer. Data consistency and data security were essential for success.

Acceptance by employees

Decisions that were previously made manually are now suggested by the digital twin and implemented by the people concerned. The involvement of everyone involved in the development process was a key success factor.

Statements

|

Due to our growth targets and complex logistics processes, we needed a smart solution. The digital twin used by Miebach made it possible to optimize our existing system, with excellent results in terms of performance and efficiency. The replenishment effort was reduced by 9%, the picking performance increased by 33% and savings of more than 175k EUR per year were achieved. In addition to their logistical and digital expertise, Miebach impressed us on a human level during the project thanks to their excellent cooperation at eye level“.

Thomas Gandt, Director Logistics, Schleich GmbH |

|

With the establishment of a digital twin, the popular Schleich animal toy figures are now handled more efficiently. The digital twin provided support for both tactical and operational issues and, thanks to a data-driven model, made it possible to simulate scenarios and find the best possible solution in a constantly changing market“.

Moritz Miebach, Head of Digital Services & Partner, |

Are you planning a project with a digital twin or do you have any questions or comments on this topic? Do not hesitate to contact us!

Contact

Germany

Michael Wegerer

Partner, Business Development Industrial Products & Mobility Solutions