| Written by Evgeny Babushkin, Xavier Farrés and Julian Maasmann

Imagine a supply chain that predicts disruptions and constantly keeps in shape. This isn’t a science fiction, it’s the best practice of continuous network optimization with supply chain digital twins.

Network optimization helps to deliver on business needs by using data analytics to support key supply chain decisions, answering such questions as: What to procure from where? Make or buy? Where should we build new facilities? When do we need to expand them? How to allocate internal production? Where to keep the inventory? For a mid- to large-size company, these decisions represent millions of Euros and a supply chain edge over competition.

The answers to these questions are relevant not only for the strategic, but also for tactical and operational perspectives. For example, deciding on an optimal allocation of global production is as important for strategic placement of facilities, as it is important for standard cost setting in annual budgeting or for defining the lowest cost response to an S&OP issue or opportunity.

The challenges with the traditional project-based approach

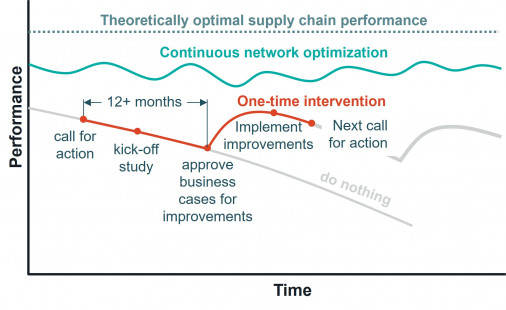

The traditional one-time intervention approach is, by design, rather reactive than proactive. The executive decision to conduct a network study often comes too late, and when the project starts – the team is not adequately prepared. Too much time is lost in rounds of stakeholder alignments, defining and staffing the team members, contracting with technology partners, collecting and cleansing data, assessing feasibility, and preparing and validating business cases. Furthermore, since the projects must compete for resources with the “business as usual”, additional time and effort is lost to identify and release the key experts from critical ongoing operations.

Because of this, even though the analytic part of a study can be completed in under 3 months, in reality, the time between the call for action and initiating the execution of network improvements often takes one or even two years.

How is continuous network optimization different?

By approaching the network optimization as an integral part of the core business processes, organizations can:

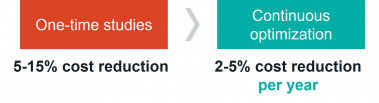

This dramatically shortens the time and reduces the effort to keep the network in shape, prevents the network degradation and adds substantial additional value to the traditional one-time intervention approach.

What are the key ingredients to enable continuous network optimization?

1. Business Process Framework

The first ingredient is a thoughtful identification, integration, and synchronization of network decisions across four core business processes:

It is important to establish clarity as to which decisions are to be made, at which level, by who, and in which sequence to ensure proper strategy development as well as alignment between the strategy and execution.

For example, a review of the site missions, CAPEX plans and make-or-buy strategies can belong to the annual long-range planning process and be done early in the year. These decisions can then be reflected in the budgeting for the next fiscal and passed over to S&OP for monthly monitoring and oversight. The master data in the planning systems that drive operational execution, such as sourcing quotas and safety stocks, can then also be reviewed and updated monthly, following S&OP reviews.

2. Supply chain digital twin

The second ingredient is a supply chain digital twin, providing technology enablement for the decision-making. The digital twin comprises of:

3. Center of Excellence

The final ingredient is the organizational framework or a center of excellence, which may be designed with different degrees of centralization and talent outsourcing. Since the network optimization gets integrated into the core work processes, the Center of Excellence has more to do with defining roles and responsibilities and developing talent, than with hiring. Nevertheless, the Center of Excellence must encompass the following areas:

How can an organization develop continuous network optimization capability?

Before investing in continuous network optimization, there must be clarity on the supply chain strategy and network development goals, as they are the base for setting optimization objectives.

The first step in the journey is to assess the network optimization needs and potential vs. the goals as well as current vs. desired maturity. This assessment is important for cross-functional alignments and securing resources. Next is to develop a maturity progression plan across people, processes, and technology dimensions as well as a roadmap with specific network optimization use cases.

There is no one-size-fits-all for such roadmaps. Some organizations could benefit by first addressing strategic use cases, such as long-range network-level capacity planning, while others would get the most value from tactical inventory parameter-setting or operational inbound optimization. Regardless of the starting use case, the early success should fuel broad organizational support and further progress.

While quick wins can be expected in under 12 months, achieving full maturity may take up to 3 years, so maintaining long-term executive leadership engagement is a must with at least quarterly reviews.

Conclusion

In today’s dynamic environment, it’s no longer enough to only optimize the network once in several years.

Continuous network optimization, taking a process-based, rather than episodic project-based approach, arises as the best practice for keeping the network in shape by preventing performance degradation.

The key ingredient to success is to embed the network optimization into long-range planning, budgeting, S&OP, and planning parameter setting processes with the help of a supply chain digital twin, as well as to establish a center of excellence that provides organizational, skill, and governance frameworks for sustained success.

Are you planning to get your network in shape? Please do not hesitate to contact us!

Authors

Evgeny Babushkin

Director, Business Development Digital Services Europe

Germany

Julian Maasmann

Senior Principal, Head of Business Unit Process Industry, Head of Industry Consumer Goods