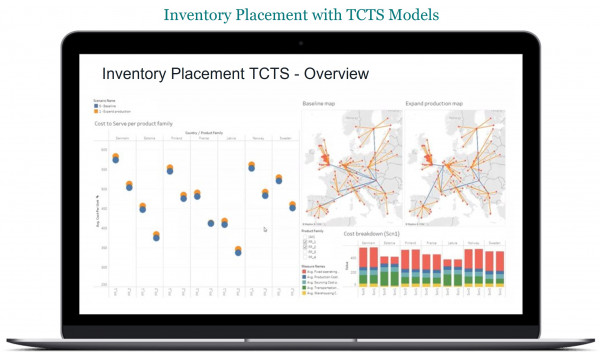

Strategic Inventory Placement: A Retail Case Study with TCTS Models

A leading retail company, managing over 20 warehouses and a portfolio of 25,000+ SKUs, faced the challenge of optimizing its inventory placement strategy. The business needed to decide between centralized warehouse placement, regional warehouse distribution, and direct market delivery. Compounding the complexity were seasonal demand fluctuations, promotional activities, and the need for better cost transparency.

To address these issues, the company collaborated with Miebach to implement Total Cost to Serve (TCTS) Models, transforming their inventory placement strategy and delivering significant financial and operational benefits.

The Challenge

Complexity and Cost Pressure

Operating in a competitive retail environment, the company faced multiple challenges:

The Approach

Optimizing Placement with TCTS Models

The project centered around building a robust TCTS Model to evaluate and optimize inventory placement. This approach enabled the retailer to make data-driven decisions that balanced cost efficiency with service requirements. Key focus areas included:

1. Comprehensive Cost Analysis

The TCTS Model provided detailed visibility into costs at each step of the supply chain—from supplier to market. Costs for transportation, warehousing, and handling were broken down for centralized, regional, and direct-to-market options.

Insights Gained:

2. Scenario-Based Decision Making

Using the TCTS Model, the company evaluated placement strategies under different scenarios:

3. Dynamic Adjustment for Seasons and Promotions

The TCTS Model enabled mid-year adjustments in inventory placement, allowing the company to shift inventory between central and regional warehouses based on promotional activities or seasonal spikes.

Results

Tangible Benefits

The implementation of TCTS Models delivered transformative benefits:

Conclusion

A New Era of Inventory Management

Through the implementation of TCTS Models, the retailer successfully transformed its inventory placement strategy. The project demonstrated the power of a data-driven approach to balance service levels, costs, and operational flexibility. By gaining cost transparency and enabling dynamic placement adjustments, the retailer unlocked significant efficiencies and competitive advantages.

This case highlights how strategic inventory placement can address complex supply chain challenges and deliver sustainable results for the future.

Stay tuned for more success stories on leveraging innovative tools and frameworks for supply chain optimization.

If you have any questions or would like to get more information about the topic, please do not hesitate to contact us.

Contact