09.10.2024

Business Challenge

This client was facing increasing warehousing costs on top of the space being insufficient to meet their demand. The primary warehouse for finished goods and corrugates would be inadequate to meet the forecasted growth, and the 3 additional warehouses for overflow were also at capacity. Looking at their future needs, they partnered with Miebach for an automation plan and roadmap that would support the 16% growth forecasts, consolidating all facilities into their primary location.

Solution Delivered

For this design, Miebach had four main objectives:

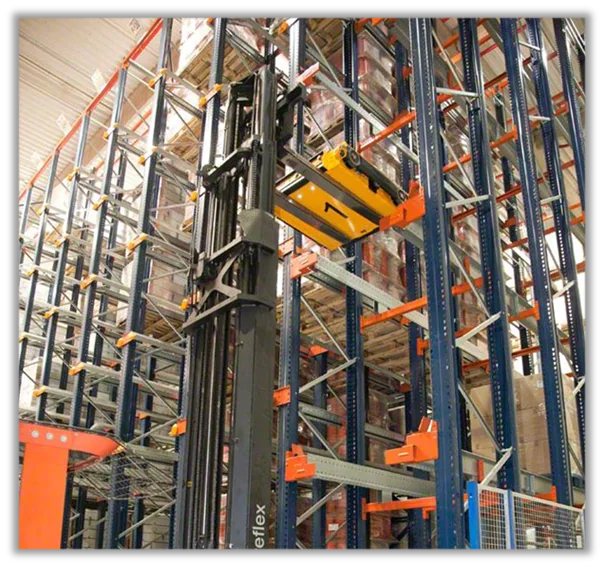

Our first task was to map the current state of all material flows from the various sites and develop the future state requirements. We worked closely with the client to develop multiple alternatives, analyzing the potential storage solutions that would meet their needs and budget allocation. The team aligned on four different storage technologies, a High Bay ASRS, a Shuttle System, a Mole System, and a Double Deep storage system with AGVs.

After thorough analysis and feedback from the client’s stakeholders, the Mole System for both the current warehouse and the expansion was the selected solution. The key factor in this selection was that the investment, which includes the construction and building expansion, technology equipment, IT, and labor costs were all within the acceptable parameters given by the client. To close out this phase of the project, a robust business case was prepared for the client showing the full implementation roadmap and investment breakdown to meet the project objectives.

Once the expansion of the primary site was selected as the solution, the team from TM Crowley & Associates were brought in to support the construction design. This partnership helped the Miebach team deliver a fully actionable solution for the client, taking into account multiple building code restrictions, such as height restrictions, number of entrances, parking spaces, parking restrictions, truck flows, and more.

Results

Author